Do you want to update the look of your metal surfaces with something new and colourful? Powder coating is the only option! The metal finishing industry has been transformed by this ground-breaking method, which produces results that are both long-lasting and striking.

Powder coating is the preferred method for upgrading furniture, improving automobile components, and giving a protective covering to outdoor structures. We will go into the world of powder coating in this blog article and examine its advantages and uses. Prepare to completely change your metal surfaces!

Powder coating: what is it?

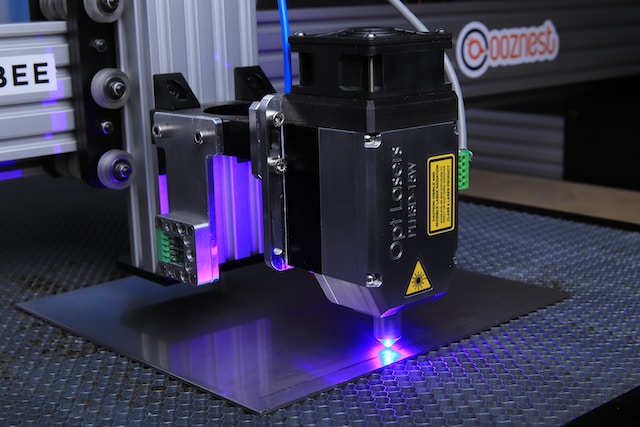

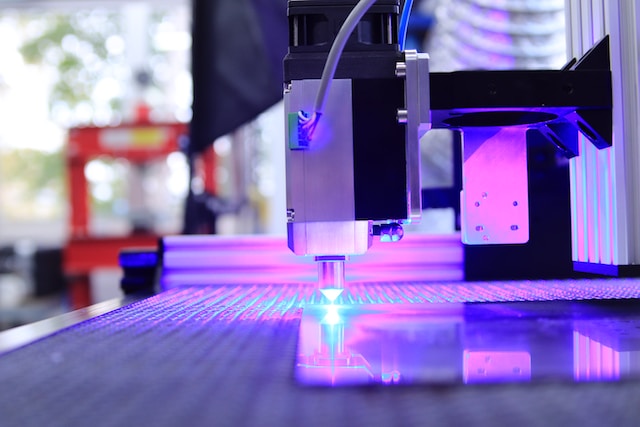

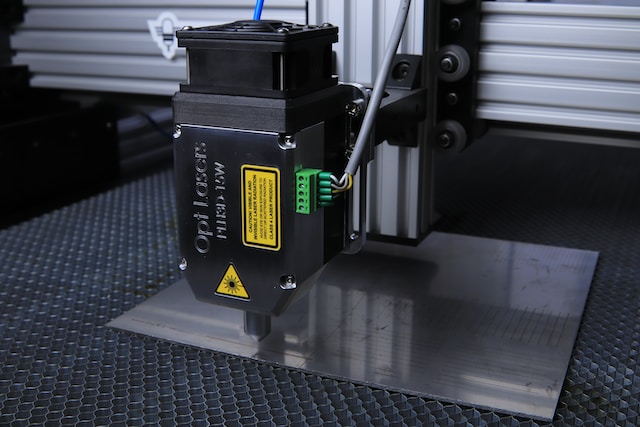

What are powder coating services? Simply described, it is a dry finishing procedure in which metal surfaces are covered with a fine powder. Powder coating does not require any chemicals to retain its consistency, in contrast to conventional liquid paint, which contains solvents. Finely powdered pigment and resin particles make up the powder itself.

The application procedure starts with the metal surface being charged electrostatically. The negatively charged powder particles are drawn to this charge and stick firmly to the surface. The metal object is coated, then after being heated in an oven, the powdered coating melts and fuses to form a smooth and sturdy layer.

The ability of powder coating to produce a homogeneous surface without leaking or running, as liquid paints frequently do, is one of its main benefits. Additionally, the amount of volatile organic compounds (VOCs) produced into the environment during application is quite low because there are no solvents used in this method.

Another advantage of powder coating is its extraordinary toughness and resistance to corrosion, fading, chipping, and scratching. Because of this, it is perfect for outdoor uses including fences, railings, patio furniture, and even automotive components.

You have a lot of creative freedom when it comes to personalising your metal surfaces thanks to the variety of colour possibilities and surface treatments offered by powder coating, which include matte, glossy, textured, and metallic effects.

Overall, powder coating is a desirable choice for increasing both appearance and use while providing durable defence against wear and tear. Powder coating has you covered whether you want to give dated furniture new life or give business-related equipment a polished look!

Gains from Powder Coating

A common technique for giving metal surfaces a beautiful and protective finish is powder coating. It is a great option for many applications because of its many advantages.

The durability of powder coating is one of its main benefits. A thick, resistant layer is created on the surface during the powder coating process, making the surface extremely resistant to chipping, scratching, and fading. As a result, the usefulness and beauty of your metal goods can survive normal wear and tear.

Powder coating offers high corrosion protection in addition to durability. The thick coating serves as a defence against moisture and other environmental elements that can eventually lead to rusting or damage. This makes it ideal for industrial machinery as well as outdoor furniture and automobile components.

The colour and finish flexibility of powder coating is another advantage. When it comes to selecting the ideal colour or texture for your project, the options are essentially unlimited. There is undoubtedly a powder coat option that matches your aesthetic preferences, whether you want bold colours or understated metallic finishes.

In addition, compared to conventional liquid coatings, powder coating is a more environmentally responsible option. Powder coatings emit very little, if any, volatile organic compounds (VOCs), in comparison to solvent-based paints, which release VOCs into the atmosphere during the application and curing processes. This makes them safer for the environment as a whole as well as the people applying the coatings.

Anyone wishing to give their metal surfaces a tough finish that can withstand the environment while yet offering a tonne of customisation choices should consider powder coating because of its advantages.

Different Powder Coating Types

There are several varieties of powder coating available, each of which meets a different set of needs and specifications. Let’s examine some of the various powder coating kinds that can modify metal surfaces.

- Epoxy powder coating is frequently used in industrial applications where corrosion resistance is important due to its outstanding adhesion and durability. It offers a robust layer of protection that can resist hostile situations.

- Polyester powder coating provides excellent colour retention and UV resistance, making it perfect for outdoor uses such as furniture for gardens or architectural facades. Additionally, polyester coatings offer good chemical resistance.

- Polyurethane coatings are a great option if you’re searching for a powder coating with extraordinary flexibility and impact resistance. They are frequently employed in applications requiring a robust finish, such as the automotive industry.

- Looking to bring things up? Metallic powder coatings have metallic particles in them, which give the surface they are applied to a shimmering appearance. For ornamental treatments on goods like furniture or signage, these coatings are ideal.

- Anti-graffiti powder coating, as the name implies, this kind of coating aids in preventing graffiti vandalism by offering a surface that is simple to wipe without affecting the underlying paint or substrate.

- Thermoplastic powders, on the other hand, melt when heated and subsequently solidify upon cooling without the need for a chemical reaction, in contrast to other powder coating types that are cured by heat alone. They have strong impact resistance and are simple to fix if they are damaged.

- Powders free of polyester’s triglycidyl isocyanurate (TGIC) TGIC-free polyester powders have become more popular as environmental concerns have grown since they are non-hazardous while still offering superior weatherability and mechanical qualities.

These are but a few illustrations of the various kinds of powder coating that are offered. Each variety has its own distinct characteristics.